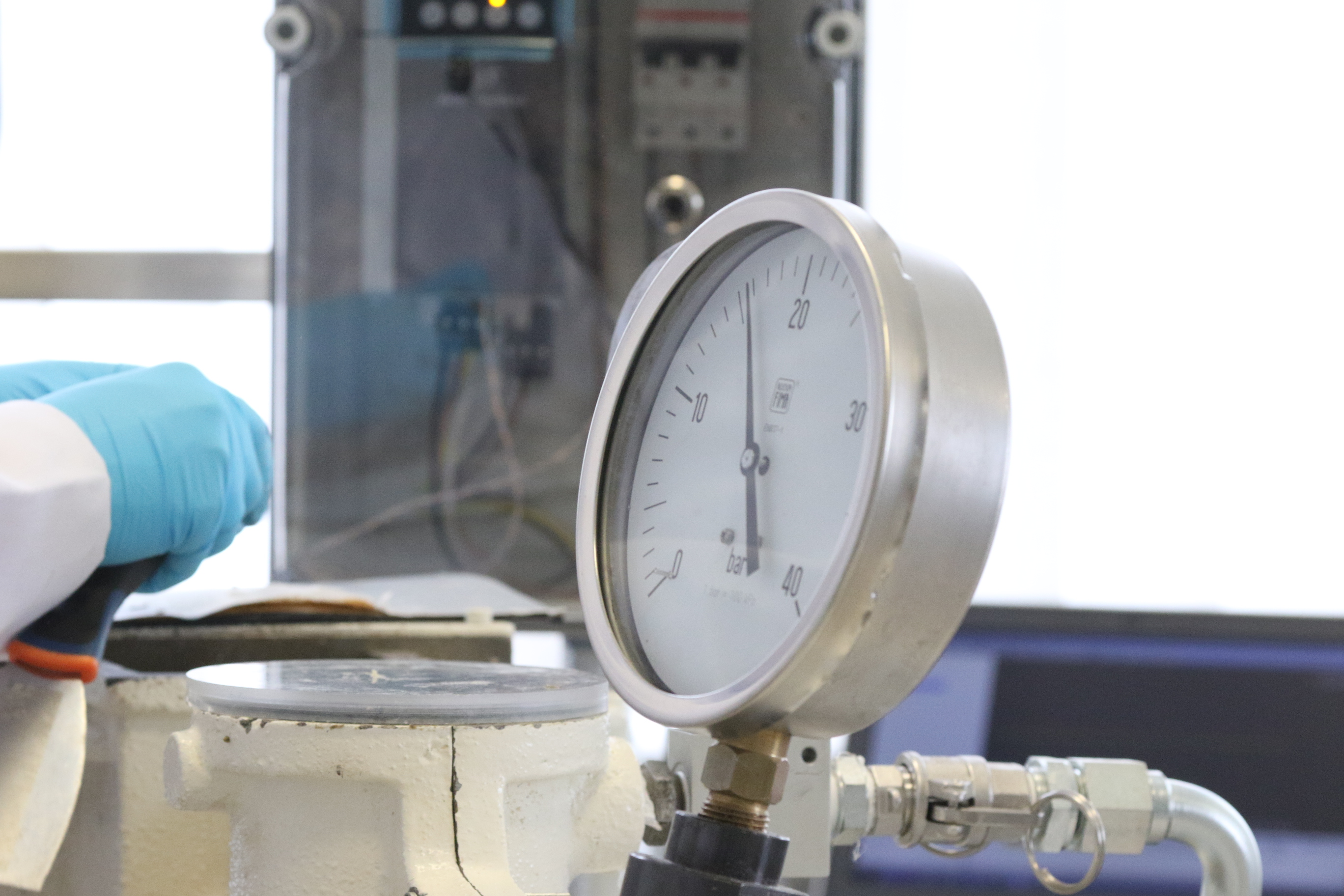

A tile’s strength is a numerical representation of how much weight the tile can support before breaking. The results are expressed in N and they may be converted into kg/cm2 using the dimensions of each tile. We are going to go over some methods that can be used to determine a tile’s strength.

STATISTICAL METHODS TO DETERMINE DRY STRENGTH OF A TILE COMPOSITION

By Rosa Mediavilla 13-Jun-2019 08:00:00

Temaer: Decorative, dry strength

This month we will focus on the importance of testing and measuring results to optimize production. Both on small and large scale, measuring and analyzing results will definitely help you increase your production efficiency.

Temaer: Question of the month, optimization

Ceramic tiles may present some issues during their manufacturing process. Most of them do not have an origin in the process itself, but in the raw materials used in the production line. A proper control in the raw materials and in the process will minimize the potential risks of producing second class materials.

Temaer: Decorative, optimization, Tools

Raw materials are the most crucial part of making quality bricks. Consistent, high quality raw materials combined with sound processes normally result in good quality fired ware. Unfortunately, in the real world, raw materials vary in quality and consistency. Variations in raw materials such as particle size, fired color, carbon content, and shrinkage are routinely measured during exploration, mining, stockpiling, and production. Another characteristic of raw materials that is critical and should be measured and monitored is the level of soluble sulfates present in the raw materials used to make brick.

Temaer: Structural, raw materials, Ceramics, Scumming, Tools

QUESTION OF THE MONTH: KEY TOOLS TO USE IN CERAMIC MANUFACTURING

By Yaiza Paños 03-May-2019 16:28:51

Measuring results is key to be able to understand how your production is going and if you should make any changes in your supply chain. In today's ceramic market, new tools to measure different parameters appear every year, making it barely impossible to be able to catch up with all of them. However, we have found several that we think might be relevant and a bit more unknown. So this month is all about tools!

Temaer: Question of the month, Plasticity, Scumming, Tools

In today’s economic climate and with manufacturers desire to ensure strong sales whilst optimizing profits what options are open to help reduce costs in production?

One could probably summarize that the “easiest” options available to reduce costs could be raw materials, production, drying and firing and reducing losses - in fact it could be argued that all of these options go hand in hand.

Temaer: Structural, Clay additives, optimization, bricks, cost reduction

In a competitive market like we have in ceramics in the last years, globalized, with common solutions to the standard production issues, differentiation in costs is the only way to remain competitive. So, how much could we save?

Temaer: Decorative, case study, optimization, cost reduction

QUESTION OF THE MONTH: How to reduce costs in ceramic production

By Yaiza Paños 05-Apr-2019 09:59:00

Reducing production costs has always been an important topic for ceramic manufacturers. There are many ways to reduce costs, but it is not always so easy to do so when you want to achieve high quality results. We can give you a few tips to reduce your manufacturing costs without affecting the final product. This month we will go over cost reduction in both decorative tile and brick and roof tile production, so don’t miss our blog posts!

Temaer: Question of the month, Clay additives, cost reduction

Decorative ceramics are characterized by fast firing cycles with values below 30 minutes in some countries. Of course this is not the standard value, but it gives an idea of how well adapted these kilns are to fast firing. At the same time, being one of the main polluting points in decorative ceramics manufacturing process, lots of efforts have been dedicated in order to reduce CO2 emissions, as well as some other highly pollutants (NOx, HCl, HF, heavy metals, Sox, VOCs, among others).

The next challenge in the horizon will be automation, though a lot of improvements have been done in order to bring self-regulation and high optimization of the full firing process.

Temaer: Decorative, optimization, kilns

Kiln firings: History, development and types of Structural kilns

By Jonathan Savage 14-Mar-2019 13:17:57

Throughout the centuries of brick and tile making the manufacturing, drying and the firing of the products has continued to evolve to ensure demand, styles and supply are met. However although manufacturing and drying are based on a small number of routes which continue to evolve the firing process has probably seen the most changes over this time frame.

Temaer: Structural, Clay additives, optimization, bricks, kilns