Plasticity is the characteristic behaviour of a ceramic material to become permanently deformed after the application of an external force. This property is the most characteristic one in clays, and there are some factors that influence the plasticity and they should be considered in plasticity measurements:

- Water physical characteristics like, viscosity, surface tension…

- Particle size distribution of the solid sample and its specific surface

- Chemical and mineralogical composition of samples

- Effect of the additives added to the clay/water system

- Sample temperature

- The way to prepare the sample, particularly the energy used to mix and to process clay, water & additives

Plasticity is defined as the capacity to be deformed without being broken. Many methods available to measure it, and they are classified into two groups: direct and indirect methods.

Table1. Direct and indirect plasticity methods.

|

|

Name |

Description |

|

Direct |

Moore (compression) |

It provides good results due to its low sensitivity to small speed modification and its independency of moisture content. It is defined as the ratio between pressures to deform a cylindrical probe up to 10% and 50% of its original height. |

|

Extrusion |

Real time process at pilot plant scale in which many parameters are recorded like amperage, pressure, throughput, consistency, temperature… |

|

|

Strain-deformation |

Compression, traction, flexion, torsion. |

|

|

Indirect |

Atterberg |

It determines humidity range in which the samples are workable, and is defined as the difference between liquid and plastic limits. Liquid limit is the maximum moisture that gives some consistency to the clay to be workable, and plastic limit is the minimum moisture for the clay to be mouldable. |

|

Pfefferkorn |

It determines the amount of water required to achieve a 30% contraction in relation to the initial height of a test body under the action of a standard mass. The results are normally expressed as graphs showing height reduction as a function of moisture content. Measuring of plasticity is based on the principle of impact deformation using a sample with a defined diameter and height deformed by a free falling plate with a given mass. |

|

|

Barna |

It is defined as the ratio between the water responsible of tile contraction and the total water; Bigot curves show this information. |

|

|

Mechanical strength |

This method calculates Modules of rupture of a small tile, by breaking it. |

Direct methods define the plastic behaviour measuring the moisture effect in the ratio between stress and deformation. Therefore, direct methods provide a more reliable measurement of plastic behaviour than indirect methods. Limitations of direct methods are related to equipment costs and time needed to prepare the sample and to run the method. These limitations make direct methods impractical when it is essential to get quick results.

Indirect methods evaluate other properties related with plasticity, like moisture content, clay consistency, mechanical strength, etc. Indirect methods are commonly used for quality control in the ceramic industries, due to their low cost and practicality. Atterberg and Pfefferkorn are two examples of these methods.

One of the main problems observed in indirect methods is that packaging grade has a strong effect in plasticity results. The lower the packaging grade, the higher moisture necessary to get a given plasticity, because the pores’ volume has to be covered by water. Pfefferkorn method has a strong dependence on packaging, while Atterberg is less dependent of that variable, because this effect modifies both limits, liquid and plastic, and it disappears after calculating the difference between them (Atterberg index).

Both direct and indirect methods can provide useful information on clay plasticity and how it is modified by the incorporation of additives to the clay. However, it is quite important to understand the fundamentals and limitations of each method, in order to avoid misreading plasticity results.

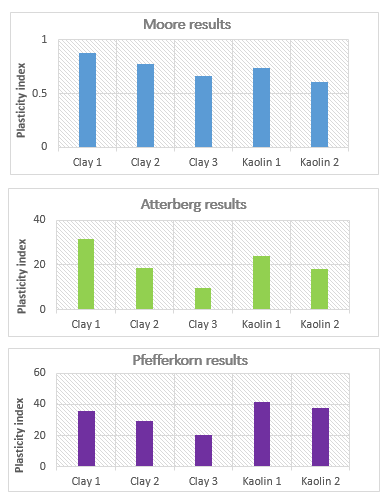

Plasticity index calculated in five samples, using three different methods are shown in the figure below. This case illustrates how different methods can lead to completely different results in the evaluation of the plasticity of a clay sample.

Figure 1. Plasticity index calculated with different methods.

Perhaps the best solution could be to work with a combination of both direct and indirect methods to establish an experimental correlation among them. The indirect method could then be used for quality control purposes since it would provide fast results. These results could then be used to predict clay plasticity in the industrial plant. In this approach it is essential to review the correlation between direct and indirect methods each time there is a significant modification introduced in the process (i.e. new clay raw materials, new additives, different clay particle size, etc).

The use of biopolymers can help to harmonize clay behaviour when production processes are changed, or even when raw materials are presenting variations on its properties.