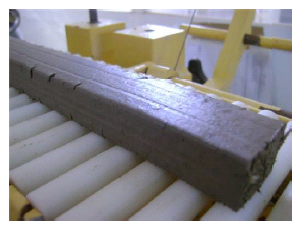

New aesthetics aligned with new technical requirements in the extrusion of ceramic bodies are demanding a new approach when it comes to additives’ requirements. In the past, lubrication and proper rheology were highly appreciated, but today there are other properties that should be taken into consideration if defects such as cracks, laminations, scumming, etc. can’t appear along the process, mainly due to the higher technical requirements of the raw materials.

New aesthetics aligned with new technical requirements in the extrusion of ceramic bodies are demanding a new approach when it comes to additives’ requirements. In the past, lubrication and proper rheology were highly appreciated, but today there are other properties that should be taken into consideration if defects such as cracks, laminations, scumming, etc. can’t appear along the process, mainly due to the higher technical requirements of the raw materials.

Plasticity depends to a large extent on particle size, mineralogy, organics, salts, etc., but it’s a key parameter in the extrusion of ceramic compositions, required for the production of very different materials, including tiles, bricks and even some refractory masses.

How it was done

Historically, several electrolytes have been used to change extrusion properties of the masses that were especially challenging, presenting a very low plasticity and generating a number of issues in the production sites. We can mention NaCl, phosphates, etc. among others, but most of them present some negative side effects, especially related to the acidic attack to the exhaust pipes in the kilns and in the dryers.

There are several minerals that can be used for plasticity improvement, as they are extremely plastic by themselves. We can mention Bentonite and also very plastic clays – ball clays – which are a good option to reach demanded plasticity while not increasing costs too much. However, in many occasions these plastic clays are influenced by geopolitics, so having a stable price and reliable source is not always easy and similarly Logistics are not easy either. High addition rates require big stocks and it can be cost prohibitive.

These minerals also present some negative effects, especially on those cases based on Montmorillonitic clays, which are known to be quite challenging in optimal drying processes.

Alternatively , very demanding bodies have been using cellulosic compounds for a long time. These capture water and, mainly due to the fact of having open chain structures, they help the clay bodies to behave as if they were more plastic, hence extrusion becomes easier. However, the drying process needs to be controlled in a much gentler way in order to avoid the appearance of cracks, even blasts may occur along desiccation if it’s too fast and retained water can’t go out, with its subsequent quality losses.

NEW TRENDS IN THE MARKET

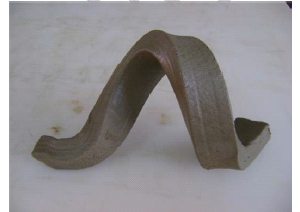

Our technical team has found an innovative alternative to these cellulosic compounds: BioKeram T. Its nature allows plasticity to be increased to the proper limits, even increasing moisture in order to reach optimum workability, without having any effect on the drying process or the quality of the final product. Very small additions of these products, in the range of 1-2 Kg per ton of clay, can bring optimal performance when it comes to plasticity, allowing hard-clay-based ceramic bodies to be extruded in optimal conditions to ensure quality, whilst having an optimal cost-performance ratio.

The presence in the market of these new products can make a difference in body formulation. Now, having the chance of amending wrong plasticity formulations at low cost and keeping standard processes for extruded bodies, the use of more demanding raw materials, more technical products, extremely dry formulas, become a non-limiting parameter in the development of state-of-the-art ceramics.