Raw materials are the most crucial part of making quality bricks. Consistent, high quality raw materials combined with sound processes normally result in good quality fired ware. Unfortunately, in the real world, raw materials vary in quality and consistency. Variations in raw materials such as particle size, fired color, carbon content, and shrinkage are routinely measured during exploration, mining, stockpiling, and production. Another characteristic of raw materials that is critical and should be measured and monitored is the level of soluble sulfates present in the raw materials used to make brick.

green strength

Brick makers put a lot of stress on their green ware when it is freshly extruded. The green ware containing 14% to 22% moisture has texture rollers applied, gets beaten by hammers, power rolled, slapped, dropped, squeezed, inverted, and stacked many layers high. The green brick have to survive these measures in order to make saleable products that meet quality standards. The characteristic that allows for brick to survive these processes or causes them to fail is green strength. How much stress can a green brick take before cracking? One way to gauge green strength is through 3-point load testing using a device such as a Hogue Tester.

Hogue tester

One type of 3-point load tester is a Hogue Tester. The Hogue Tester was developed, built, and used by Carlton Hogue. Carl was born in Wisconsin in 1921 and developed the Hogue Tester while working for LignoTech. Carl built the devices in his workshop in Mesquite, Texas, making improvements to the devices with each iteration. Carl was very active in the brick industry up until his death in 2008. There are several Hogue Testers in use in the brick industry by various companies.

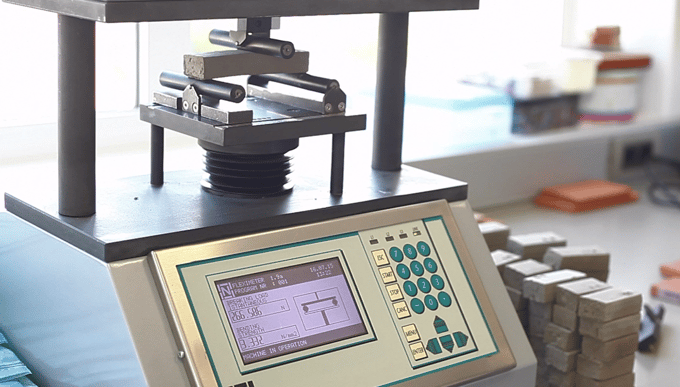

A Hogue Tester uses hydraulics to apply a center load to a green brick that is supported underneath at two points. The machine applies the load slowly and uniformly and shows how many pounds per square inch it takes to cause a crack in the green brick. The device uses either one or two pressure gauges depending on the model and can also be used to measure dry strength.

measuring green strength

To measure green strength using a Hogue Tester or some other type of 3-point tester the first step is to make sure the unit is turned on, the pump drive is running, and the appropriate gauge is selected whether it be for green or dry strength testing. Next you place a full green brick in the tester making sure it is lined up properly so that the brick is evenly supported by the two supports and so the load will come down on the center of the sample. Once the sample is in place, start the testing by pressing the start button. The unit will then apply pressure to the sample until the sample cracks. The unit will then reset. The pounds per square inch can then be recorder from the gauge where the maximum pressure is indicated by the maximum needle. In order to avoid anomalies it is a good practice to test multiple samples.

controlling greeN strength

As they are the most important part of the brick making process, raw materials play a huge part in green strength. The proper ratio of sand, silt, and clay sized (colloidal) particles is one of the keys to making a green brick that will stand up to the stresses that they are exposed to in forming, setting, and drying.

The processes that the raw material go through from grinding through extrusion also have an effect on green strength. Grinding equipment that is sized properly or maintained will not produce the particle sizes desired which can result in lower green strength as surface areas are reduced and the particles cannot form strong bonds. Mixers that are not maintained will not homogenize the clay mix which can result in a loss of green strength, laminations, or both. The pug mill, vacuum chamber, and extruder are also keys to controlling green strength. Worn out pug knives, sealing augers, extrusion liners, and extrusion augers can result in a lack of homogeneity, laminar flow, excessive heat, or lack of compaction. Any of these factors can result in a lack of green strength. Insufficient vacuum can reduce the green strength of the best engineered raw material mixes.

Clay conditioners that homogenize the clay mix, reduce water usage, and allow for clay particles to flow can be used to enhance green strength. Improvements up to 30% can be observed using a device such as a Hogue Tester to test green strength.

Please be sure to contact us if you have any questions.